| Search results - "install" |

0000 LR Bluetooth dealer Kit install instructions1583 viewsThis 17 page pdf is mostly a series of pictures showing how to install the original Land Rover dealer installed Bluetooth kit for circa 2005 / 2006 three's. Also included are three wiring diagrams sheets related to the pairing code 0000 Bluetooth install.

This pdf is useful if you are now removing the 0000 kit to install the optical 2121 MOST D4 module, an easier install than the 0000 kit ever was.

|

|

Fog Light & Washer Jet Install90 views

|

|

Fog Light & Washer Jet Install86 views

|

|

Thankfully it\'s nearly a week old. they wanted to dig underneath my drive to install gas. Nov 5th, Bang,78 viewsNo, and i was worried about the rangerover!

|

|

Here it is - long awaited Mantec plate in action directly after being installed! Thanks again John!!!169 views

|

|

195 viewsSwitches installed in the roof panel

|

|

234 viewsThe cable loom for the lights (installed by 10forcash)

|

|

214 viewsReady for installation

|

|

261 viewsOriginal Frontrunner brackets, but installed upside down to reduce the total height

|

|

Installazione Ganasce Freno di Stazionamento30 viewsRimozione ed Installazione Ganasce Freno di Stazionamento

|

|

Llamsrecovery mode installation53 viewsSpring lock inconspicuous

|

|

Geosat2 GPS installed498 views

|

|

MONITOR INSTALLATO100 views

|

|

This is a normal H7 HID bulb installed in a BMW headlight to show glare above cut off line96 viewsThis is what the light pattern is that causes glare in most retofit applications including some projector lights. this is in fact a projector headlight on a BMW but the old projectors were only actually half projectors and half reflective bowls. the beam pattern should be clean cut like this ___/

|

|

94 viewsOut at the C pillar. From here wires were threaded through the rear seatbelt anchor point into the commercial box, which is the hub of all the wiring and CarPC installation

|

|

D4 2010 installation57 views

|

|

D3 installation64 views

|

|

yes, i am cutting it...26 views

|

|

Chinese touchscreen + GPS + USB reader + Bluetooth + DVD32 viewstrying to install this touchscreen

|

|

dvd install26 views

|

|

dvd install26 views

|

|

dvd install21 views

|

|

dvd install23 views

|

|

TravAll Dog guard installed and waiting for passengers163 views

|

|

new screens fitted 26 viewsAfter installation

|

|

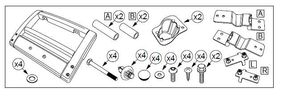

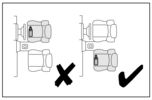

Locking Kit626 viewsready to install

Mfd from https://www.facebook.com/DifferentialPartsUS

|

|

solar roof install437 viewsMore or less wrapped up my solar installation today. I added a Grape Solar Flex 100W panel, it's adequate to keep the vehicle topped off with the Fridge running, and Ham, but it could lose some ground if transmitting depending on how much, 2 would be awesome. One is enough, but barely. I am quite impressed with the Grape Solar flex panel version 2.0.

https://www.facebook.com/DifferentialPartsUS

|

|

solar panel install347 viewsAt least at this point, I mounted it by using Clear Silicone RTV. This stuff is kind of like glue, but can be removed. If it doesn't hold up after curing and driving, I'll remove it and come up with another plan. I used heavy cable ties on the 4 grommets, in case it lets loose, it won't take out my wiring and the car behind me. 2 Panels are dandy like this, but I don't want to permanently block the roof space. Grape Solar to power my snomaster fridge

|

|

Traxide USI-160 Install493 viewsOverview picture of Traxide USI-160 upgrade install. This was an upgrade from the SC80 which performed flawlessly. The USI-160 had two relays and can deliver more amperage. As a result, the wiring was upgraded to 4/0 Welding Cable (warn) and heat shielding was added. The unit performs flawlessly to support 2 HAM Radios, Fridge, etc. Like me https://www.facebook.com/DifferentialPartsUS

|

|

semi-final install247 views

|

|

new parts waiting to be installed2 viewsImage uploaded in thread 177818

|

|

INSTALLAZIONE COMPLETA95 views

|

|

INSTALLAZIONE COMPLETA ED ACCESO114 views

|

|

Land Rover Stop Tail Light dual filament bulb nominal 12 volt 21 / 5 watt filaments1412 viewsThis is the Land Rover part number 264590 dual filament bulb, (P21/5), that inserts into the upper two tail lamp receptacles. In the upper one, both filaments function, in the lower one, only the 5 watt tail light filament functions.

I regard it as not a good practice to routinely switch bulbs when the tail light filament, (5 watt), burns out on the lower bulb. The broken filament can jiggle over onto the brake light filament, (21 watt), and short the circuit to ground or something else not predicable.

There are also arguments to say that quality control is better on the Land Rover marketed bulbs than say far east sourced bulbs. Filament construction, and hence resistance can vary and mislead the current sensing circuits monitoring the signal light systems. Also when the bulbs are properly installed, all filaments should be standing vertically and not at any slope.

These are the sort of obscure circumstances that can lead to false trouble messages on the display, dropping to the stops, and subsequent concerns - all over a tail/signal light bulb.

For example, the filament life of both the tail light and the brake light filaments in the P21/5 bulb is significantly less than the USA common 1157 dual filament bulb, (1000/250 vs 5000/1200 hours); brightness in the P21/5 is a bit more, (3cp/35cp vs 3cp/32cp where cp is candle power), but current consumption is oddly less, (0.44a/1.86a vs 0.59a/2.10a where a is amps). It is the quest for efficiency vs maintenance trade off.

|

|

Compressore 12 volt 88 viewsEcco il compressore installato nel vano 2° batterie del Discovery3.

|

|

OEM Sat Nav Install30 views

|

|

Air Distribution and Filtering Systems2046 viewsThis is 3 page pdf with coloured drawings of the air distribution ducting for the front air system.

Also included is a sketch of the pollen filter location within the front heater ducting. Note that two types of filters are available: a) the cheaper dust/pollen filter and b), the activated carbon filter that removes smells from the air. Installing the more expensive activated carbon filter means you never smell a cattle truck or chicken farm again. It really works.

|

|

501-12-cool-box install instructions / german language63 viewsCool Box Discovery 4 installation instructions - german version

|

|

D4/LR4 501-12-floor console upper panel install instructions / german language64 viewsD4/LR4 501-12-floor console upper panel install instructions / german language

|

|

Navi Becker and iPod285 viewsThe Becker Highspeed II was installed in the bin with power connected. Works great, even TMC worked inside the garage right away!

|

|

Tools from dealer110 viewsThis is a cel pic of the tools from the dealer for install and removal of control arm bushings. minus one broken tool.

|

|

124 viewsThis is the installation guide from the manufacturer

|

|

Rosen A7 \'alternative\' install459 views

|

|

1084 views

|

|

1179 views

|

|

1388 views

|

|

1492 views

|

|

Thread upload2 viewsImage uploaded in thread 187641

|

|

Add A Circuit Littelfuse Data sheet2264 viewsThe switch connects to what Littelfuse brand calls an Add-A-Circuit model FMH200BP which is an adapter that plugs in place of a Mini fuse and then has space for two Mini fuses, (original and a second one). In this install, only the original 5 amp fuse was used - adapter was so as to route power from fuse box thru fuse, then rocker switch, and then back to fuse box.

Before you install the Add A Circuit for this application, take an ohm meter and trace out the circuit path of the four slots that fuses could insert into. The path is more complicated than one might first think. As such, the orientation of the fuse holder in the socket matters for this application - that is for a circuit diverter, rather than accessory adder.

|

|

Land Rover Aerial Fin images for both Glass and Metal Roof Disco3 / LR3850 viewsAs well as the two different fins, this pdf also shows the plastic blanking plate for glass roof vehicles where no fin is installed.

The glass roof fin is secured by two security screws from the top into a plastic frangible glue on gasket. The hope is that when struck, the fin will shear off and not crack the glass roof. Re the metal roof design, the fin is secured from underneath via two nuts.

The pdf also shows the various electrical bits related to the antennas. In the UK, the fin would house not only a cell phone antenna but the TV and satellite radio antenna electronics as well; in the States, the Sirius sat radio antenna and a G type cell phone antenna if the phone kit was installed would reside within the fin. The SAT NAV GPS antenna is located within the High Mount Brake Light plastic mounted to the upper rear hatch.

|

|

Fin cell phone aerial drawing190 viewsThe factory aerial for the factory NAV / GPS on my 2005 HSE is within the high mounted stop light lens at the top of the upper hatch door. I do not have the factory installed phone kit, and as such, do not have the fin installed; instead there is just a plastic blanking insert to fill the cell phone aerial wiring hole in the metal portion of the roof; hence this requirement for an "external" cell antenna. For those that do have the fin on their glass roof, the fin is screwed on to a glued on plastic gasket, (sort of), and not bolted thru as per the metal roof 3's.

|

|

7 views

|

|

Thread upload4 viewsImage uploaded in new thread

|

|

Altox WBUS-4 Installation in Discovery 3125 viewsstep by step with pictures how to install the Altox WBUS-4 in the Discovery 3 in footwell

|

|

Altox_Installation_on_D3-RRS_up_to_200936 views

|

|

how to install Altox WBUS-4 in engine room on Discovery 395 viewsthis is to show how to install the Altox WBUS-4 in engine room of a Discovery 3, but i would recommend to install it inside car in footwell, see other PDF in this album

|

|

Setup Web application for Altox WBUS-458 viewshow to setup the Web application for Altox WBUS-4

|

|

11 views

|

|

38 views

|

|

199 viewsInstallation Instructions for ACM

|

|

151 viewsInstall Hands free HCB-700 in A class

|

|

Aux Battery showing ground cable bolt "upside" down 1568 viewsIn order to obtain sufficient height clearance to get the plastic cover back on, I had to install the ground cable to the underside of the battery post connector.

Note the battery vent hose, (approx 5 ft required) is run down into where the windshield washer fluid container is located. There is not much electrical or metal in that area to be corroded by battery gas plus the open end of the vent hose tends to be protected from dirt and stays clean as well.

|

|

BCI Group 40R Deka 640RMF battery showing vent hose run forward to windshield washer reservoir area 1424 viewsRecessed post "Euro profile" battery to "match" OEM and stock Land Rover bracket; note that the Traxide SC80-LR module is mounted at an angle to allow for the main cable to sit under the cover so cover still closes.

The battery is a nominal 7", (180mm), high, but sits on a 1" battery spacer set under to raise the bottom front end of the battery such that the approx 11", (290 mm), length of the BCI 40R battery rises above the angled plastic nibs at the forward end bottom of the case front; hence sufficient space, (1/4", 5mm) remains at the brake reservoir end.

Also the 40R battery does not have hold down "flanges" on each end; on the sides yes, but not the ends so no additional length is required.

When I had to replace the 40R, this time I installed the shorter, (9.625"), taller, (7.5") Interstate BCI 47 / DIN H5 battery which eliminated the spacer on the bottom and better fit the stock LR tie down bolt lengths. Deka also has a BCI 47 / DIN H5 that would work fine as well.

|

|

D4 Auxilliary or Second Battery installed in Aux Battery Box214 views

|

|

D4 Auxilliary or Second Battery installed in Aux Battery Box, Vents Circled188 views

|

|

A Pillar Black Plastic cover install pdf - new type.1029 viewsThis 3 page LR pdf explains how to install the newer A pillar plastic covers and avoid instant water leakage as a result of the new design.

|

|

Battery Disconnect side post with + & - caps, top view616 viewsThis disconnect is designed for side post batteries. It can be used on either the + or - terminals. It can also be installed at the "other" end of the battery cable as well. In my install of the Aux battery, I installed this on the negative ground cable where the cable attaches to the body sheet metal. I have never used it but it seemed like a good idea at the time. The main battery hookup is pure stock.

For the hot side of the Aux battery, an Anderson PowerPole was used inline for the cable between the Aux and connecting to the spare bolt hole at the + post of the Main battery cable.

|

|

Brake Light Switch, Find, Remove, and Install Instructions 7782 viewsThis is a two page doc outlining where to find the brake light switch, how to remove it, and then install the new one.

Note, do not move the brake pedal when removing or installing the switch. Let the brake pedal hang where it wants to. The switch design is actually cunning, and as such is supposed to make the removal and install fool proof. Hence if you think too much about it, you can wreck the new switch.

If you want to inspect the interior of the switch, wait until you have removed the old switch. You can then just unsnap the blue from the white to get it apart. Inside, the switch is quite simple, (no circuit boards), but it will probably show black dust from failing contacts.

I think the reason the switch fails is that the Normally Open, (NO), contacts of the brake light contacts were made too light to carry the current load for make and break of the tail light filaments. I also think the black dust created then fouls the Normally Closed, (NC), second set of contacts for the ABS circuit. As such, the Normally Closed contacts become intermittent in operation and display as a fluctuating open and closed circuit condition to the ABS system when the ABS should be seeing a steady closed circuit. Hopefully the replacement switch contacts are more robust and may be as I recently replaced my switch again just as a matter of maintenance. While in a redesign, ideally the NC contacts should be sealed or at least separated from the NO contacts, when I inspected the removed switch, this time there was no black dust present.

Probably the removed switch will have a Land Rover oval logo moulded into it, the new one, FOMOCO.

|

|

Brake Switch Visible thru Opening4934 viewsThe blue and white bit is the switch; the sort of gold appearing box,(it is really black), you will not see in your 3 as it is a Smooth Talker brand amplifier for my Blackberry phone antenna. This install is detailed in the SmoothTalker phone antenna section of my gallery.

One way to remove and install the switch is to lower the "horizontal" panel above the brake pedal as shown where the flashlight head is located. To actually remove the switch, you slide your hand thru the gap and rotate the switch clockwise 1/4 turn while watching thru the rectangular opening. Installation of the new switch is the reverse of above - 1/4 turn counterclockwise.

Before you remove the switch, note its orientation - horizontal with electrical wires to the left. That is the way it should look after replacement as well.

The second time I replaced the switch, I did it all thru the rectangular opening and did not remove the horizontal panel - that is experience helping out.

The knee kick you have to remove regardless. It is sort of hinged at the bottom so you just pull at the top and sort of rotate the knee panel and then pull upwards for two plastic "fingers" to clear the slots they reside in.

|

|

Black Deposits on Brake Light Switch Plunger2731 viewsThis jpg I got off another forum and is typical of what one will see when one opens up the removed brake light switch. The black powder is residue from arcing of one of the pair of contacts within.

Hopefully the newer switches with the FOMOCO logo moulded into the plastic are improved from the Land Rover logo marked early units, however I doubt it.

The Ford part number is SW-6572 and/or 7E5Z-13480-A as used on the 2006 to 2009 Ford Fusion's and Mercury Milan's; the Land Rover part number is XKB500110. Cost of switch could be about twenty five dollars. A previous LR part number for the switch was XKB500030, so hopefully the newer LR part number, XKB500110, reflects some improvement in reliability.

It is possible that the new switches are better as I installed a replacement 72,000 km, (45,000 miles) later, at 195,000 km (121,000 miles). When I took the removed switch apart to inspect, it was clean inside. There was no black dust - the switch looked like new, hence they must be improved now.

|

|

Breather line with factory cap cut off.2276 viewsIf you expand the jpg by clicking on it, in the bottom right corner if you look closely, one can see the black plastic factory vent tubing with the OEM cap cut off.

Note the tubing is cut at a 45 degree angle facing to the rear. Also shown in the top right is the cut off portion sitting on the coolant water hose and on the top left also sitting on the coolant hose, the new to be installed Gore manufactured replacement breather cap.

|

|

Breather Cap Installed1971 viewsThe black L shaped tube is is the Gore manufactured, (the Gore-Tex people), LR4 Breather Valve installed in an LR3. Naturally the installation looks similar to what one sees on an LR4 or RRS as the Gore breather valve is now OEM for new production.

The part number of this upgraded front differential breather valve is LR019450 and costs about thirty dollars.

|

|

New Breather Cap installed.1675 viewsThis shows the new Gore brand angled breather cap installed. The cap points rearward to the firewall. Also shown is the cut off piece.

The new Gore breather cap is what one now sees on the LR4 and RR Sport.

|

|

109 views

|

|

338 views

|

|

Fuel Burning Heater Install36 views

|

|

Snow Chains Installed - Land Rover LR3HSE94 viewsSnow Chains that seem to fit a Land Rover LR3HSE

|

|

I placed the mic for the hand free at the steering colum - easy install and seems to work fine139 views

|

|

Job done - after adding nice start screen :-)237 viewsPinoeer AVIC-F910BT installation

|

|

39 views

|

|

Cubby fridge installed in 10 minutes44 views

|

|

Installation completed67 views

|

|

179 views

|

|

176 views

|

|

143 views

|

|

135 views

|

|

160 views

|

|

181 views

|

|

176 views

|

|

153 views

|

|

150 views

|

|

175 views

|

|

206 views

|

|

141 views

|

|

142 views

|

|

145 views

|

|

227 views

|

|

163 views

|

|

102 views

|

|

ARB Front Locker in Disco3111 viewsA bit of a challenge for the installer since it was the first they had done but all done and nice and tidy.

|

|

ARB Front Locker in Disco3117 viewsA bit of a challenge for the installer since it was the first they had done but all done and nice and tidy.

|

|

Fuel Burning Heater Install Instructions (not mine, sorry)572 views

|

|

D3 Kaymar Rear Bar Fitting Sharing17 views

|

|

Part 1 of the LF Inset in Grill Installation221 viewsDetailes of the Grill preparation as well as the modifications needed to the front end.

|

|

D4 hid kit installed and outside in the dark 6000k conversion.284 views

|

|

D4 hid installed in light ready to go213 views

|

|

84 views

|

|

D4 Gvif Unit Fitting13 viewsHow to fit Gvif unit to a D4 sat nav screen

|

|

Wires installed for roof console122 views

|

|

Deka Battery Dimension Data613 viewsThe battery size that I installed for my auxiliary was a BCI 40R battery as it was for me the easiest to fit and was also a cranking battery. The case profile was such that no tie down fins were located on either bottom end, (sides yes), and length wise, it was only about 11" (290 mm) long. As such, I did not have to grind the nibs at the front bottom of the plastic surround.

I did however raise the bottom of the battery above the angled nibs as I set the battery on a 1" (25mm) high plastic spacer. The total height, (battery plus spacer), was about 8" (200mm) so the battery top still fit under the Land Rover factory cover.

For the Aux battery, when I replaced the 40R, I installed an Interstate BCI 47 which is similar in size to a DIN H5. I was therefore able to eliminate the vertical spacer as the Group 47/H5 is the same height as the DIN H7/H8 stock LR spec starting battery. As such, the standard battery tie down bolts can be used without modification. The Group 47 battery is 9 11/16" long x 6 7/8" wide x 7 1/2" (190mm) high.

|

|

Headlight mod and D4 grill mod62 viewsFirst tackle of mods to my D3, First attempt was the D4 grill, then the de-orange of the headlands, Also installed LED sidelights and indicators

|

|

FIle con tracce GPS103 viewsFile compresso con le tracce GPS del tour Disco3Romagna 2009.

Istruzioni per l\'uso.

1) Verificare di avere installato Google Earth

2) Scaricare e decomprimere il file

3) Aprire il file cliccandoci sopra: si apre Google Earth con le tracce visibili.

E\' possible fare il tour automatico (Google Earth vi fa vedere il giro (che è stato diviso sui due giorni in vista aerea) oppure semplicemente guardare le zone che più vi interessano dall\'alto.

|

|

gvif scheme79 viewsSchema for gvif installation using reversing camera, wireless caravan camera, hitch camera and camera select when driving forward direction

|

|

Discovery III Multimedia Installation v1.1159 views

|

|

Discovery III Multimedia Installation v1.2187 views

|

|

UHF Radio installed20 views

|

|

Thread upload4 viewsImage uploaded in new thread

|

|

310 views

|

|

286 views

|

|

290 views

|

|

303 views

|

|

273 views

|

|

310 views

|

|

DLR relay install65 views

|

|

ARB Bull Bar Installation, Front side view. Colour coded to Vehicle.295 views

|

|

I-Pod installed into my Disco 3451 views I-pod video and Geosat2c installed. No visible damage to the deskboard, no holes etc.

|

|

Wind Deflector for Rack14 viewsRecognise this part? Its the lower front recovery point cover. Installed upside down to silence the wind "drone" on the roof rack - works a treat!

|

|

new conquest on the way to get the LR wheels installed203 views

|

|

BAS FBH Controller Installed 188 views

|

|

ARB333 viewsARB Bullbar and Warn tabor winch, with detachable tow ball(not installed).

|

|

Hella Micro DE installation to S model Disco290 views

|

|

Smoked stripe on the windscreen438 views Installed 5 % foil into windscreen to hide the rear mirror tft lcd display a bit from the possible thiefs.

|

|

Rear mirror with LCD TFT display installed459 views

|

|

Driving lights installed432 viewsinstalled with Defender styled alu parts

|

|

Retrocamera61 viewsRetrocamera installata nel porta luci della targa

|

|

Hidden winch mount with winch in place122 viewsHydraulic hoses are now installed. Note notch for hydraulic:electric solenoid to fit in mount.

|

|

Front bumper view of semi-installed winch118 viewsNote the left-side (looking forward) bracket holding the white windscreen washer bottle.

|

|

Installed winch with hydraulic hoses175 viewsThe hydraulic hoses are stiff, so I had to run them up the side of the radiator (can just see inside red boxes) to near the top of the radiator, then back down inside the engine compartment, then underneath the engine (behind the radiator) to the D4's power steering rack, where the hoses become metal. This hose routing may not be possible if the fuel-burning heater is in place (we don't have those in Aust and the space allowed room for my hands to bend and run the hoses without kinking).

|

|

Close-up front view of partially-installed winch120 viewsNote that the sheet-metal flange just above the winch had to be notched to allow winch controller to be actuated. Also this same bracket had to be bent upwards to allow the winch hydraulic:electic solenoid to fit without rubbing. The nut on the upper-left bolt (the one with a very faint circle around it) stripped on re-installation, so the tray and winch pulling load is held only by the threads on 7 bolts....

|

|

Front-right view (looking forward) of partially installed winch and mount122 viewsThe closest bracket, with three rubber grommets, is the air bag sensor. Before beginning any of this work, be sure to disconnect battery and discharge any remaining electrical power. I didn't want to accidently drop this assembly and cause the airbags to deploy.

|

|

Installed winch with electrical solenoid connections158 viewsI routed the electrical supply (2 small wires) up the side of the radiator. You can see the unconnected wires inside the red boxes. I ended up connecting them on the radiator diagonal strut with cable ties. They are out of the way for any deep water transits there.

|

|

Installed winch, with bumper partially re-installed202 viewsPutting the D4 back together. Shows the tools and owner lying about.

|

|

Installed winch electrical wires146 viewsWires which only power the solenoid are inside spiral wrap. They are also connected inside the wrap at the high point of the loop. Cable tied into place to prevent vibration rubbing.

|

|

View of both hose connections to power steering system149 viewsBoth connections are shown. My friendly Qantas hydraulic hose expert cut off the elbow and modified it so I can re-install it to the PS rack before warranty work (and certainly before the vehicle is lifted off the body!!).

|

|

Winch as installed176 viewsLicence plate is held on by winch cable and 4 metal pins which fit into modified bumper body. Winch rope is green

|

|

271 views

|

|

SmartNav speaker & button installation507 views

|

|

DVD Installed175 views

|

|

DVD Install 2188 views

|

|

139 viewsbracket installed into existing mounting holes for coolant reservoir

|

|

122 viewsExisting threaded holes to install plate onto

|

|

120 viewsThe plate installed on top of the bracket

|

|

DVB-LR Installation Instructions Pages 1-440 views

|

|

DVB-LR Installation Instructions Pages 5-837 views

|

|

DVB-LR Installation Instructions Pages 9-1356 views

|

|

10.2" DVD player installed519 views

|

|

Rosen 7500s installed123 viewsrosen 7500

|

|

The Tablet Installed 15 views

|

|

11 views

|

|

Thread upload2 viewsImage uploaded in new thread

|

|

160 views

|

|

The Tablet Installed 26 views

|

|

Fluid, Filter/Pan Combo removal and install5950 viewsThese are the LR instructions re removal and install of the plastic pan/filter combo for the ZF 6HP26X transmission on the 4.4L petrol V8 LR3.

The instructions tend to ignore the reason you have to lift the right hand side of the engine about 40 mm. This is because of a frame cross member that interferes with dropping down of the plastic pan. The real problem is a vertical "oil filter spout" that rises out of the filter/pan combo up into the transmission. The spout is the suction pipe for filtered transmission oil back up into the tranny.

On the metal pan versions, the filter is separate from the pan, hence the filter remains with the tranny when the metal pan is dropped. The filter is then removed or installed independent of the metal pan, hence with the metal pan, there is no need to lift the engine.

If one is removing the plastic pan so as to install the metal pan, then some do not lift the engine but just drop the plastic pan enough to gain access to saw off the vertical plastic spout - it is a one time procedure.

Be aware however that the metal pan uses a flat gasket and the plastic pan uses a O ring like perimeter gasket that sits in a half round groove in the tranny casing. Also the metal pan uses 21 shorter torx M6x22.5 metric cap screws for the perimeter bolts. The plastic pan uses longer M6x28.5 torx metric cap screws.

|

|

Thread upload1 viewsImage uploaded in thread 198799

|

|

Ford 6R60 six speed cutaway showing torque converter.2188 viewsThis is a cutaway of the Ford 6R60 six speed which is a Ford license built version similar to our ZF 6HP26 six speed speced on early 3's.

The newer 3's and 4's have the ZF 6HP28. The Ford version is called the 6R80 and variations of it are used on the Raptor. As such, the Raptor metal pan can be installed on the 3's tranny but the deeper Ford Raptor pan does not have a drain plug.

|

|

Thread upload8 viewsImage uploaded in thread 130828

|

|

Thread upload6 viewsImage uploaded in thread 136532

|

|

Thread upload7 viewsImage uploaded in thread 130828

|

|

Land Rover TSB LTB00245 install instructions1898 viewsThis is the Land Rover Technical Service Bulletin showing how to install the new breather cap. The instructions are a bit vague re cutting the existing air vent tubing on a 45 degree angle with the cut facing to the rear.

|

|

Thread upload6 viewsImage uploaded in thread 154160

|

|

Thread upload1 viewsImage uploaded in thread 188863

|

|

GOE Sensor Rod Installation12 views

|

|

FBH GSM Kit Installation Guide61 views

|

|

GVIF Manual64 views

|

|

gvif install89 views

|

|

Headrest videi install136 views

|

|

156 views

|

|

Curt Manufacturing brand hitch, assembled but not installed.282 viewsThe Curt Manufacturing hitch is an alternate to the Land Rover removable "plow" hitch. Once bolted in place, the Curt hitch is always there.

The Curt part number is 13456. It is a Class III hitch with a 2" square receiver and designed for a maximum 600 pound tongue weight.

The hitch hangs below the rear bumper but does not stick out past the bumper; also the "donut" spare tyre can still be installed / removed; am not so certain about a full sized fully inflated spare.

|

|

Curt Manufacturing Installation instructions Class III339 viewsThese are the instructions for installation of the Curt Hitch.

|

|

Rhino Tow Loop Hitch263 viewsThis is a receiver end view of the Rhino Hitch that ties to the factory tow loop. In addition to improved strength, it does not reduce ground clearance as does the factory style when installed.

Land Rover in early advertising videos when the 3 first came out showed the D3 hanging from a crane via the frame. The intent was to show how strong the frame is and by inference, the rear tow loop, specifically noted as being good for 6 tonne. The video ends before anything dropped or was lowered back to the ground, so one of course does not know for certain. The Rhino Hitch design however picks up on the apparent evidence of strength and certainly the additional clearance.

|

|

Thread upload190 viewsImage uploaded in thread 162283

|

|

Received & Tested96 views

|

|

Ipad dash install98 viewsIpad install on dash

|

|

front of D3 with DS2 installed70 viewsPair of Rigid DS2

|

|

Side protection bars installed.48 views

|

|

Before side protection bars were installed.39 views

|

|

Mud flaps installed.39 views

|

|

D4 battery tray installed34 views

|

|

Traxide SC80-12, D4 tray and Optima D34 installed41 views

|

|

Close up - Solenoid14 viewsA close up of the solenoid which is installed close to the auxiliary battery bay.

|

|

The on/off switches of the multimedia headrests14 viewsThese switches were installed to power on/off the previously installed gamecube and the screens attached to it.

When I removed the gamecube and lately the screens as well, I was clever enough (surprised as well) to leave the switches and all the wiring that I had running around.

They came in handy when I installed the multimedia headrests and are now adding an extra power on/off control of the screens.

|

|

Fuse box in the rear12 viewsI installed the fuse box in the rear. Since I do have a 5-seater, there's plenty of space in the booth beneath the 2nd cover, which rests behind the second row seats.

|

|

Outside connection to the compressor14 viewsFrom the compressor which is in the booth, the air hose runs to the back of the car.

I was able to install the connector in the space of the second trailer plug (which wasn't installed anyway).

|

|

President Johnson II in its current position16 viewsThis CB was installed some years ago and still is at the same location.

However, I'm planning to move it to the head unit area.

As such, I'm looking around to replace my low end head unit with a single DIN radio and the CB on top of it.

|

|

60 viewsFinal setup, everything in place after about one full day of work, which included removing quite some bits I had installed before.

|

|

iPod aux connection14 viewsPictures of installation of iPod into d3 cd player

|

|

led install101 views

|

|

iPod connection11 viewsPictures of plug pins break in solder and finished installation Jack lead iPod connection

|

|

iPod installation9 views

|

|

DRL Loom Installed12 views

|

|

Webasto TC4 Pre-installation check23 views

|

|

Aux battery fuse box16 viewsMy install of a fuse box.

|

|

Monitor 8" LCD installato101 views

|

|

Installing Ballast Resistor to Vehicle loom162 views

|

|

Installing Ballast Resistor to Vehicle loom172 views

|

|

Oval Timer Installation44 views

|

|

D4 Lights Installed121 views

|

|

Switch is blue colour thing thru the rectangular opening.3149 viewsThe blue coloured plastic bit thru the rectangular opening is the brake light switch. The fist time, I found it easier remove the switch by dropping the horizontal plastic panel, (two screws), and then slipping my hand in and rotating the switch clockwise 1/4 turn. The second time, I was able to remove the switch thru the rectangular opening and did not need to remove the horizontal lower panel. Obviously, I had to remove the sloping knee pad panel, (note sort of hinged at the bottom so pull back from the top.)

Regardless, do not touch the brake pedal - just let it sit where it wants to. One has to first remove the angled knee pad panel that sits under the steering wheel. It can be pulled from the top corner at the door side. Pulling releases a pair of those U shaped metal clips that LR loves so dearly. You have to pull quite hard. The bottom is held by a couple of plastic fingers in a couple of slots so you pull at the top till the two clips release and then rotate the panel and pull upwards a bit.

To remove the switch, you rotate it clockwise and pull outwards. Rotating the switch clockwise automatically retracts the plunger back into the switch body away from the brake pedal arm.

Similarly when you install the new switch, the required 1/4 turn anti clockwise rotation action releases the plunger so it lays up against the brake pedal arm and at the same time, secures the switch in place.

To remove the electrical wires, the switch will drop below the horizontal pad and hang from the wires so unclipping the electrical connector plug is fairly easy to do.

|

|

DVD Headrest Install Console Removal132 views

|

|

DVD Headrest Install Console Removal120 views

|

|

DVD Headrest Install Console Removal124 views

|

|

DVD Headrest Install Console Removal126 views

|

|

DVD Headrest Install Console Removal121 views

|

|

DVD Headrest Install Console Removal124 views

|

|

DVD Headrest Install Console Removal123 views

|

|

DVD Headrest Install Console Removal126 views

|

|

DVD Headrest Install Console Removal128 views

|

|

DVD Headrest Install Console Removal122 views

|

|

DVD Headrest Install Console Removal138 views

|

|

first Headrest installed 62 viewswork in progress

|

|

A pillar mount installed166 views

|

|

Finished the install!254 views

|

|

Blackvue Installation47 views

|

|

AV connector for RSE60 viewsdecided to install AV connector in Cubby box between seats (no fridge in my car) so I can store an iPod hidden in there to provide media for Rear Seat Entertainment

|

|

460 viewsPrevious installation.

Only my GPS, Mobile and MP3 changer in the back (controller seen on later pictures)

|

|

461 viewsFirst step in the journey, installed USB ports.

At the time I installed these, the goal was to use them in combination with the car-computer that resided in the back.

In the meanwhile, I dismantled the car-computer and nearly everything that was connected to it (touchscreen front, Wifi, DVB-T ...).

I kept the USB outlets in the front and turned them into charger for the appliances missus brings with her when we're on holiday. Mainly her iPod and smartphone ...

|

|

433 viewsA glimpse of the final installation, with a working map-reading light. In case the GPS doesn't work ;p

This is an old picture as the touchscreen is removed already.

However, I kept the reading light.

|

|

471 views@ home, we have 2 remote controlled garage doors. So I installed the remote controller in the car, added 2 buttons and off we go. Lucky me the controller worked at 12V anyway :D

I'll add a LED onto that one, so I'm sure it works when I press :)

|

|

Paddock dog guard view from rear283 viewsInstalled; can see the mounting points

|

|

Switch centralina sospensioni36 viewsImmagine dell'installazione dello switch della centralina sospensioni

|

|

960 views'Rotronics' 3 stage battery management system installation

|

|

951 viewsAuxillary battery installation

|

|

Towing/Dual batttery installation613 views

|

|

Newly installed Freelander2 headrest monitor9 views

|

|

New Rear Seat Entertianment System newly installed15 views

|

|

VMS & custom binnacle94 viewsVMS system and custom-made binnacle installed where LR factory satnav screen would be fitted.

|

|

Centre console in black62 viewsnew mount installed for tom tom, thanks to Brucey for the use of his skills

|

|

Removing the center console in preparation of installing the Drive+Play components.442 views

|

|

This is a night photo of the completed installation. The controller and screen brightness can be adjusted.499 views

|

|

This is where my iPod will live, unless I need to take it out to add songs or update playlists.491 viewsI installed a rubber grommit between the cable and the hole to keep it from rubbing on the sharp plastic.

|

|

Installation64 views

|

|

airbox with EGR blanking kit installed 16 views

|

|

Thread upload31 viewsImage uploaded in thread 92518

|

|

Subwoofer Install275 viewsThe subwoofer and waffle cover removed from the space in the tailgate.

|

|

Subwoofer Install232 viewsThe bolts on the waffle are either sealed or welded on. Couldn't get them off with a good hammering, so had to cut them off.

|

|

Subwoofer Install234 viewsGrinding & sanding down the waffle ridges gave about 1/4" more room for the new sub.

|

|

Subwoofer Install265 viewsThe OME sub and the new sub (Pioneer TS-SW2541D)

|

|

Subwoofer Install246 viewsThe waffle cover all grinded & sanded down.

|

|

Subwoofer Install224 viewsDrilled new holes in the waffle cover to fit with the new sub.

|

|

Subwoofer Install271 viewsThe stock sub has 2 sets of wires running to it. Both of these wires lead back to the stock amp.

The new sub only needs two wires - a positive and a ground. So, we just cut the stock wiring harness off the wires in the tail gate and wired them together. On the other end of these wires, we did the same thing.

|

|

Subwoofer Install244 viewsWent with Rockford Fosgate Punch amp to drive the subwoofer.

|

|

Subwoofer Install239 viewsAfter grinding & sanding it down, painted it black.

|

|

Subwoofer Install269 viewsMoved things around a bit in the "component compartment" to house the amp addition.

|

|

136 viewsA Class Hands free phone install HCB-700

|

|

Thread upload0 viewsImage uploaded in new thread

|

|

26 views

|

|

15 views

|

|

install in footwell13 views

|

|

Thread upload25 viewsImage uploaded in new thread

|

|

Thread upload6 viewsImage uploaded in new thread

|

|

Thread upload7 viewsImage uploaded in new thread

|

|

Thread upload8 viewsImage uploaded in thread 159496

|

|

Installing a Fuel Burning HeaterTimer Remote v1-0364 views

|

|

Installing a Fuel Burning HeaterTimer Remote v1-1.pdf419 views

|

|

Thread upload8 viewsImage uploaded in thread 199969

|

|

16 views

|

|

Thread upload29 viewsImage uploaded in new thread

|

|

Interstate Battery Dimension sheet640 viewsThis sheet is hard to find - the sheet is not on the Interstate corporate web site but some dealer web sites display it. The pdf shows most of their available batteries including the H7 and H8 sizes that are the LR North America replacement batteries for the main starting battery. These batteries are of the Land Rover desired "shallow" cycle high discharge current Maintenance Free, (Ca Ca), internal construction, (not AGM, but instead, Wet Flooded Lead Acid with battery "caps" and Ca grid separators).

For the AUX battery , the H6, (BCI Group 48), is probably similar in dimensions to the Varta E12V75N that is popular in Australia. For that battery to fit in the second battery compartment, you must grind out the angled nibs on the inside front bottom of the LR black plastic surround, something I did wish to do and hence installed a Group 40R on a spacer. Alternately, one can choose an Interstate BCI Group 47 which is similar to a DIN H5 for the AUX location. I did this when I had to replace my 40R. No vertical spacer is required and the stock battery tie down bolts and clamp work well.

|

|

iPod cradle234 viewsThe dealer used the phone fitting and the iPod was installed via cinch connectors. Volume is controlled via the audio, charging function also included.

The sound even with the basic Audio system is terrific!!!

|

|

Replacement switch from RRS installed on LR3861 viewsThe switch shown is LR part number YUZ500020, the upper rear hatch release switch that is found on the Range Rover Sport.

The switch body is the same switch as on the LR3 except that there is no wiring disconnect on the LR3. Hence when the switch corrodes and requires replacement, the LR solution is to purchase a new handle and license plate light assembly. I instead cut off the old switch and installed a JAE mating connector to the existing wiring and hence just plugged the RRS switch in.

The replacement RRS switch snaps into the same rectangular space in the same manner as the removed LR3 switch, the difference is the JAE male wiring connector.

|

|

JFC50098028 viewsMy current installed unit.

|

|

John Guest DOT all plastic fitting714 viewsThis is a picture of the John Guest DOT all plastic union. If you look closely, you can see the DOT imprinted in raised letters on the end of the fitting. This is of a 1/4" connector rather than the 6mm that the 3 requires.

The picture is similar to the air suspension pneumatic fitting union that Land Rover sells as replacement part # STC8580. This is for 6mm OD tubing size. The STC8580 comes with what are called "Collets" at each end that cover up the press to release feature underneath. See the John Guest web site www.johnguest.com under the Pneumatics section and also in Downloads for their catalog for install and remove instructions.

The actual "air brake spec" fitting that Land Rover provides has an interior 4mm OD ferrule that slips inside the 4mm ID of the nominal 6mm tubing. I have not yet been able to obtain the John Guest part number for the LR fitting, only the LR part number. This part number was generated for the RR Classic air systems.

|

|

John Guest (LR part # STC8580) push in straight 6mm tubing to tubing connector727 viewsThis picture is similar to the air suspension pneumatic fitting union that Land Rover sells as replacement part # STC8580. This is a 6mm OD tubing size push in to install straight tubing to tubing fitting. The STC8580 comes with what are called "Collets" at each end that cover up the press to release feature underneath. See the John Guest web site www.johnguest.com under the Pneumatics section and also in Downloads for their catalog for install and remove instructions.

The actual fitting that Land Rover provides has an interior 4mm OD ferrule that slips inside the 4mm ID of the nominal 6mm tubing. Hence the fitting depicted and part number are not actually correct. I have not yet been able to obtain the John Guest part number for the LR fitting.

The fittings that show in this doc are what I call food service fittings rather than transportation or Air Brake fittings. The part LR sells, (STC8580), is the Air Brake type for transportation.

|

|

KDB500010 D3 Fire Extinguisher2 viewsInstallation instructions for D3 fire extinguisher.

|

|

Thread upload11 viewsImage uploaded in new thread

|

|

Kenwood v1000 AV-Controller Install Diagrams127 views

|

|

Installed nudge bar today322 views I was quite easy and quick to make. Took only 2 hours, easy job.

|

|

Next I will install additional high beam lights314 views

|

|

L319_MK4_ALTOX_GSM_remote_control_installation_manual37 views

|

|

LA501-024 - Technical Bulletin - Dealer Installed Door Moldings61 views

|

|

7 viewsLampguards front installed

|

|

8 viewsLampguars front installed

|

|

instructions for Webasto timer install202 views

|

|

Thermostat Housing LR005631528 viewsWhen the time comes to install a new thermostat, consider installing the whole housing instead.

Advantages are the thermostat is correctly installed, (not as simple as it should be); you get all new plastic and that is important, plus a new coolant temperature sensor and also a new heater coolant bypass valve, the secret part no one realizes is also within.

The cost of the whole assembly is not much more than the cost of a factory thermostat and the effort to replace all is not as difficult as it might seem.

|

|

Here it is attached to the caravan "A" frame.631 viewsThe cable ties are temporary until I can drill and tap a couple of holes for screws.

|

|

OSRAM DLR/FOGLIGHT Installation Manual27 views

|

|

Littelfuse Mini Add-A-Circuit FMH200BP and OFH0200ZP1610 viewsFound this jpg somewhere on the forum - others are using them as it is a good way to tap the fuse box to add a fused circuit, or in this case, to modify a circuit to add a switch such that the fused circuit is switched. In my SmoothTalker gallery, there is a PDF from Littelfuse specifically related to this Add-A-Circuit device.

Before you install the Add A Circuit for any application, take an ohm meter and trace out the circuit path of the two pair of slots that fuses could insert into. The path is more complicated than one might first think. As such, the orientation of the fuse holder in the socket may matter depending upon the application. If the application is a circuit diverter, (as the F35 mode is), as opposed to a mere accessory adder, orientation matters.

|

|

LLumar AIR80 Air Blue 78 windscreen film IR reduction metal oxide339 viewsThis pdf summarizes the characteristics of the various types of window glass film available from LLumar. www.llumar.com

I had the Air 80 metal oxide sort of clear film, (windshield film they call it), installed on the front driver and passenger side windows to reduce the Infra Red penetration and hence heating effect on the front occupants. The film is barely visible from either inside or outside, however there is a noticeable reduction in heat penetration when sitting inside. In short, my arm does not get cooked.

Cell phone and GPS etc seem unaffected by the metal oxide film.

I also had the film installed on the three sun roof portions as well.

|

|

458 viewsCompleted install of control panel.

|

|

388 viewsCompleted Install of Control Panel. Wiring goes up into headliner, over curtain airbag on left hand side, and down the B pillar.

|

|

Air Suspension ECU Fuse 35P cut off switch.3802 viewsThis shows the SPST rocker switch mounted in the blank plate installed in lieu of a manual passenger side air bag shut down switch - now automatic via passenger seat pressure switch. Fuse 35P (5 amps) is located in the interior fuse box behind the lower glove box and protects the ignition power supply to the Air Suspension ECU. When the SPST switch is moved to the OFF position, the RAISE /LOWER switch on the centre console is not powered, and hence does not function. As such, some signals from the wheel height sensors and CPU are ignored. By itself however, removing F35P will probably not stop the 3 from self dropping, particularly after the engine is turned off.

Fuse F3E, (5 amps), located in the engine bay fuse box by the starting battery protects the circuit that provides feedback to the Air System ECU indicating that the Compressor Relay has successfully operated and that the Air Compressor is or should be operational, can also be removed, (but is probably not totally necessary), as it gets its power thru F26E. Hence Fuse F26E, (20 amp), also located in the engine compartment fuse box is the fuse that must be removed. This fuse protects the circuit that provides full time battery power to the Air System ECU. When in place, current thru the fuse powers the periodic re-levelling action, (usually lowering a bit with that brief air release noise), that often occurs when the vehicle is parked and the engine is off.

Removing F26E fuse will stop the auto levelling action and also inhibit any other down to the stops signals, (engine running or not). When F26E is removed, no power can flow thru to F3E, hence removing F3E is more for insurance than an absolute requirement. The same with F35P, removing F26E removes primary full time power from the Air Suspension ECU, and hence removing the F35P fuse should not really be required either as long as F26E has been removed.

|

|

Battery Maintainer pigtail sticking out of Grill723 viewsThis is all you see when everything is put back together - just the pigtail and Weather Pack blanking plug. Most often, I have it all tucked back behind the grill.

In winter, there may be a second cord hanging out as well - the 120 VAC power cord for the engine block heater, a tea kettle like element inserted in the engine block. NAS petrol V8's do not have the Fuel Burning Heater, (FBH), installed, but instead in cold area markets have the block heater element assembly available as a dealer installed option. There is an argument to say that the heating element is factory installed in all cold climate V8 gasoline engines, however the appropriate power cord is not. If true, this means that all one needs to purchase is the area specific power cord and plugging in / attachment to the engine block located block heater.

As such, you will often see a conventional 120VAC three prong power plug hanging loose out of the grill of most vehicles here in the wintertime. In summer, most drivers tuck the plug back behind the grill as it is no beauty mark.

|

|

Boot lighting panel, finish side up 307 viewsThe above jpg shows the two 15 LED light assemblies as well as the SPST rocker switch mounted beside the W5W Land Rover supplied light.

The reality is that with the recent development of LED lighting that can replace a W5W T10 bulb, one can almost achieve the same results just by installing a LED bulb within the factory light.

|

|

Compressor Con Rod Broken 1745 viewsThe model number of this compressor is RQG500060; the model number of my replacement compressor was LR015303, the unit that was apparently being installed on the D4 vehicles as of Spring 2010. As of Fall 2011, the new replacement part number is LR023964, the same as in the 4's.

Note the number hand written on the black plate. All the compressors seem to have some number hand written on them - hand built I presume, and every unit perhaps evolving a bit differently as LR struggles to build a compressor that will last. I guess Hitachi, (the manufacturer), should be given credit for that.

|

|

View from front left side looking towards rear aux battery compartment under cover 643 viewsAs there is no Fuel Burning Heater in the NAS V8 petrol vehicles, there is space available to install the FASKIT panel here. The piping is such that each air spring can be isolated from the air system and then filled one at a time manually via the Schrader valve. There are five Schrader valves and five shutoff valves. The fifth valve nearest the gauge controls air from the compressor, and can provide fill up air via a jumper fill line assuming the compressor is still operational.

|

|

Empty space in NAS LR3 for location of FASKIT panel595 viewsThe empty space is available as the North America Spec gasoline engine LR3's do not have the Fuel Burning Heater installed. The air lines from the four air springs and the air tank will appear to rise up from under the headlight assembly. The lines to the front block valve assembly located behind the front right fog light will sort of run within the bumper across the front of the radiator down into behind the righthand fog light. The rear lines somewhat follow the path of the existing air feed line from the front valve assembly to compressor. Rather than be located between the left front fender liner and left metal wing however, the four lines will feed thru the empty wing space inside and above the wheel well arch and exit down by the left front mud flap. From there, the lines run along the left frame member above the air tank and then parallel the frame over top the compressor to the top of the rear left air spring where the rear air block valve assembly is located.

|

|

0.032" OD metal fishing leader and lead fishing weight clamped to existing wire rope 2105 viewsI used a size #0 lead fishing weight as a clamp to attach the 0.032" diameter flexible wire rope fishing leader to the release cable.

The pictured weight is the smaller #00 weight, however it did not work very well so reinstalled with the larger #0 size. I clamped to the cable as what breaks is the L retainer that is hidden in the actuator and holds the cable. When the L breaks, it lets go of the cable so you hear the clicking but there is no opening action.

Clamping on to the cable is an attempt to resolve that reality; also if the actuator electrically fails, the release mod should still do the task. Note in the picture the two Torx T15 screws that hold the gold plate to the plastic case and also the two 8mm cap screws that have to be loosened to remove the actuator from inside the door.

|

|

NAS 7 Pin Round Socket + 4 Pin Flat Socket oriented as installed.742 viewsThis is the layout you see when you look into the NAS Land Rover sockets as installed at the rear of the LR3/4. The flat 4 pin socket is located under the round socket.

Wiring order is relative to the slot on the round socket, and hence the same as the other jpg where the slot is shown at the top.

The CJB monitors the front and rear turn signal lamps and can detect if more than four lamps are fitted, (the side turn signal lamps are not monitored). This is another reason for using genuine LR bulbs as off shore bulbs can have varied and out of spec resistance values.

When a trailer is detected, the trailer warning indicator in the instrument cluster is supposed to flash green in synchronization with the turn signal indicators.

If one or more of the turn signal lamps on the vehicle or the trailer are defective, the trailer warning indicator will cease to flash any longer. This is to alert the driver to probably bulb failure.

If the trailer has LED lamps installed, and no LED adapter circuitry is used, most likely the trailer will not be sensed and systems such as the backup sensors will not be disabled.

|

|

Plastic cover and Box back on in Front of Radiator 636 viewsThe wiring loom is below the cover - nothing is crushed or distorted and all fits back together OK. The black plastic box with the DPDT, (centre OFF), toggle switch is to tie the battery maintainer to each of the two batteries per the Traxide Dual battery install. I can also get power to the power door locks if all fails.

|

|

relocation of stuff to allow gigantic battery installation. The hood/bonnet barely closes wihout trouble.381 views

|

|

Land Rover Brake Light switch XKB5001102675 viewsThis is what the switch looks like when removed from the parts box. Note that the plunger is recessed back into the body and when installing, the process of rotating the switch body 1/4 turn anticlockwise releases the plunger so it pops longer and engages the brake pedal. If you look down on the plunger you can see curved slots where the rotation takes place.

Do not try to rotate the new one - play with the one you remove. Also do not press on the brake pedal when removing or installing as you will damage the plunger - this is one of the reasons the plunger is retracted into the body for installation. It is also for this reason that if you try to confirm the operation of the switch contacts with an ohm meter by pressing the plunger, the switch will appear not to function as one might anticipate. Have faith, the switch will however, once installed and the plunger is in full motion.

|

|

Thread upload1 viewsImage uploaded in new thread

|

|

Thread upload2 viewsImage uploaded in new thread

|

|

Rosen A10 Land Rover Installation Manual831 viewsThis is a 11 page pdf which is the Land Rover version of the A10 installation manual for our 3. It consists of a hundred plus sketches showing how and where to connect various cables, conductors and plugs.

|

|

LR 6HP26 transmission oil part number TYK5000501413 viewsThis jpg shows the genuine Land Rover transmission oil, part number TYK500050, for the 6HP26X tranny. The Shell product number is M-1375.4 but you cannot buy the oil retail from Shell. The container size is one litre.

A routine oil change where the pan/filter combo is not changed takes about 3.5 to 4 litres of oil. When the tranny is brand new, a dry fill can take up to 9.5 litres of oil however around 7 litres is more common for when a new pan/filter combo is installed on an already in service transmission.

|

|

LTB00105 - Technical Bulletin - Steering Gear Removal and Installation63 views

|

|

LTB00118 - Technical Bulletin - Removal and install Front Lower Suspension Arm106 views

|

|

LTB00119 - Technical Bulletin - Remove Install Engine and Ancillaries60 views

|

|

LTB00121 - Technical Bulletin - Remove Install Automatic Trasmission Valve Body Assembly68 views

|

|

LTB00145 - Technical Bulletin - Remove & Install Parking Brake Cables89 views

|

|

LTB00156 - Technical Bulletin - Remove & Install Expansion Tank59 views

|

|

LTB00184 - Technical Bulletin - Remove and Install DVD Autochanger57 views

|

|

LTB00189 - Technical Bulletin - Remove and Install Parking Brake Actuator101 views

|

|

LTB00207 - Technical Bulletin - Body Side Molding - Installation Procedure59 views

|

|

LTB00293 - Technical Bulletin - Fuel Tank Availability Installation140 views

|

|

Typical XTC install128 views

|

|

How to cable factory BT module (including MOST bus connector)82 viewsInstructions to install Factory BT module in a Disco 3 that has LR aftermarket or no BT module installed

|

|

322 views

|

|

Right after install292 viewsHere is the left front Terra Grappler right after install. My they\'re big!

|

|

Thread upload2 viewsImage uploaded in new thread

|

|

Overview of engine compartment from Main Battery side, (Passenger, LHD), looking across to Aux Battery749 viewsNote labels on main battery cover. The one you cannot read says that an auxiliary battery is installed on the other side. This is to warn service people should they wish to shut off all battery power.

The main starting battery is supposed to be of CaCa separator construction and DIN H8 or BCI Group 49 size. This means Calcium separators Wet Flooded Lead Acid, 13.9" long, 7.5" high and 6.9" wide.

On the Aux battery cover is a label saying to disconnect the blue Anderson single pole connector located under the cover by the brake reservoir. BCI Group 40R battery is small enough that the cover goes back on.

|

|

Traxide SC80-LR644 viewsKit -- cable was 6 feet short. Check to ensure the length is adequate prior to installing it.

|

|

traxide ground 666 viewsTraxide Install - Left hand drive Ground Strap in place.

|

|

warn winch controller installation607 viewsremotely installed due to space limitations, and to keep the unit dry. Left Hand Drive, fitted in engine bay near washer fluid fill for reference point.

|

|

warn winch controller installation541 viewsremotely installed due to space limitations, and to keep the unit dry. Left Hand Drive, fitted in engine bay near washer fluid fill for reference point.

|

|

warn winch controller installation566 viewsLeft Hand Drive, fitted in engine bay near washer fluid fill for reference point.Remote control unit fitted on the box. Remotely installed due to space limitations, and to keep the unit dry.

https://www.facebook.com/DifferentialPartsUS

|

|

rear socket install1387 viewsTraxide rear socket installation, alternative location. These holes must be precisely in this location because there is little clearance to the right of left due to the blower motor and hoses, etc.

|

|

rear socket install1022 viewsShows to white cable run, cable routing, cable ties and socket placement. Rear sockets fitted. Note the white power cable, and cable tie location. The socket in this position are neatly back out of the way, but handy.

|

|

rear socket install825 viewsThis photo shows the rear sockets installed, shows how the sockets in use are tucked up nicely and out of the way.

|

|

rear socket installation complete635 viewsThis demonstrates the rear sockets installed, shows how the sockets in use are tucked up nicely and out of the way.

|

|

rear socket installation complete671 viewsdemonstrate a neat and roomy install

|

|

radar detector wires tucked up high424 viewsThe orange ties hold wiring sockets for floodlights (to be installed). Red tie holds excess wire for radar detector.

|

|

wires tied up tight539 viewsThe Orange ties hold wiring sockets for floodlights (to be installed). Red tie holds excess wire for radar detector.

|

|

D44 Winch stainless fairlead654 viewsThe completed D44 winch installation, including the stainless fairlead. A stainless trim plate, and NA license plate holder is on the way.

|

|

aftermarket and factory BT module52 viewsnotice the additional MOST connector (with white protective cap) for the factory install module

|

|

Traxide installation - rear cable19 views

|

|

Installato167 views

|

|

Thread upload1 viewsImage uploaded in thread 177571

|

|

Thread upload3 viewsImage uploaded in thread 177571

|

|

Fuse Panel showing F35P Add A Circuit installed1230 viewsFive amp fuse F35P is located towards the top left in this jpg. The other three Add A Circuit devices are for other items - powering my cell phone base etc.

Note the orientation of the Add A Circuit as this matters. Also one can just see a red tab sticking out from behind the device. The red is the conductor crimp end of a narrow 2.8mm male spade type connector that inserts into one of the "fuse" slots.

|

|

Thread upload3 viewsImage uploaded in new thread

|

|

242 viewsHands Free Install HCB-700 screen posision

|

|

247 viewsThe two installed modules with preliminary wiring for testing.

|

|

329 viewsInstallation slowly proceeding. You can see the controller cables inserted into the notch I made with a dremel.

|

|

255 viewsAlmost completed install. Just the controllers need mounting.

|

|

256 viewsCompleted install with both receivers working.

|

|

352 viewsCompleted install, again with aluminum bar and 3M velcro.

|

|

301 viewsCompleted install. I used a bar of aluminum bar with 3M industrial velcro to hold the controllers.

|

|

remove metal clips from floor panel and reinstall on to the plastic trim293 viewsIf you leave the clips in place and try to force the trim back in the clips are knocked through the floor unit and it takes an hour to get them out!!

|

|

camera installed in towbar cover.359 viewsthere is a plug on the power and video connector so can easily be removed for towing

|

|

camera all installed - same size as a sensor381 viewscant go in centre of panel due to towing hoop

|

|

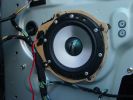

Pioneer TS-SW1041D 10" sub installed120 viewsAfter cutting off the factory sub mount studs, it took ages to bash the indents. To gain more space behind the driver - I changed the driver\'s side license plate from plastic push in lug - to stainless bolt with nyloc nut. Cr@ppy paint job in wrinkle-finish - all I had on hand at the time. Sealed and treated lower tailgate with Dynamat.

|

|

New Rubber26 viewsToday my new Pirellis are installed.

|

|

Yanav PX3 Tesla Style Screen Installation63 views

|

|

Back view of Brodit holder with Ram 1" ball long arm installed27 views

|

|

Modified D4 mount with ball installed26 views

|

|

Redundant Parts972 viewsThese are what you are left with once the EGR blanking kit is installed. Best to hang onto them in case you need them again!

|

|

Front Blower R16 relay, part number YWB500060473 viewsThis is the front fan relay located in the engine compartment fuse box. It should be replaced and installed new when a new fan is installed.

|

|

Air Compressor 70 amp replacement relay1384 viewsThere is a software update, 09 April 2010, LTB00270, for the compressor which reduces the shut down pressure to about 205 psig (14 bar). The update is usually done when changing to a new compressor and also includes replacing the R7 relay in the engine compartment fuse box, 07 DEC 2010 LTB00331.

The newer grey case coloured relay, part # YWB500220, shows to be rated at 70 amps, (the relay, not the compressor), however the previous black case coloured relay also indicates 70 amps.

Both the new and replaced relay show on their wiring diagrams to have a parallel voltage spike resistor, (probably 560 ohms), across the coil terminals, #1 and #2. This means one does not just replace the relay with any four prong 70 amp ISO sized relay that one happens upon.

One presumes the grey relay is either upgraded or just being installed for good measure. The relay is common on Ford Fiesta for the seat heater relay, Ford part number 5M5T 14B 192 EA; also Volvo, part number 30765034. The Tyco part number moulded on the grey body is V23136-J4-X62.

|

|

Thread upload34 viewsImage uploaded in thread 44435

|

|

Reservoir Air In fitting installed 1648 viewsSchrader valve installed. Shop air can now be introduced into the tank to facilitate the raising of the 3 when there has just been a failure of the onboard air compressor rather than the electronics or valve block wiring etc.

Air could also be sourced from this point, however the purpose of the modification is air in, not air out as the air pressure normally runs above 200 psig, too high to be safe for routine use unless a pressure reducing regulator is added per the Mitchell Bros kit.

|

|

Reservoir Air In fittings exploded view 1885 viewsThis shows the fittings required for the mod. The reducer adaptor requires a 27mm socket and is M20 x 1.5 male thread x 1/4" NPT female. The 1/4" male NPT Schrader valve has the standard valve core removed and an AN/MIL spec aircraft oleo strut valve installed instead.

A standard automobile valve is rated at 200 psig, (14 bar); the air tank runs closer to 244 psig, (16.8 bar), with the relief valve set to open between 334 psig, (23 bar) and 370 psig (25.5 bar). The aircraft valve is rated at 2,000 psig, (138 bar).

|

|

Reservoir Bung 24mm socket 1149 viewsThis is the view of the air tank at the end nearest the front left wheel. This is what you see before you do the mod. The other view is after the mod.

On pre 2008 models, there is this 24mm socket hex head bung, M20 x 1.5 thread, that can be unscrewed and the Schrader valve assembly installed instead. On newer 3's the bung hole was deleted from the front end of the air tank; hence the mod as described, is then not possible.

|

|

Rhino racks installed!215 views

|

|

RAI installed183 views

|

|

Rosen A10 Manufacturer Installation Manual759 viewsThis is a 30 page pdf from Rosen that explains how to install the A10 unit. It is Generic in nature and hence carries detail not found in the LR specific install instructions. It also uses words and pictures instead of just pictures, hence can be a bit easier to figure out, particularily if you wish to take advantages of some of the hidden features not described in the LR material.

One of these features is how to hook up to a headrest display or I suppose even to the NAV in front.

|

|

Rosen Owners Manual879 viewsThis 28 page Owners Manual is the Rosen version written specifically for the A10 model DVD Video Game Entertainment System player that may in attached to the roof of your 3.

Discussed is how to use the remote control, the wireless headphones, the TV feature if installed, and how to change from 16:9 widescreen format back to the older 4:3 format.

|

|

At the beach462 viewsInstalled the rails to bring home the Christmas tree. Installed them myself & quite proud of that fact since I\'m not the mechanically inclined type hehe.

|

|

NAS 7 pin + NAS 4 pin Flat Trailer Socket304 viewsThis is the vehicle end of the NAS trailer harness that is located behind the removable plate centered within the rear bumper by the towing loop. Re the four pin flat connector, from the bottom, the exposed bare lower pin is the ground, usually the White wire on a NAS trailer. The next pin up is normally a Brown wire on a trailer and is for the Tail Lights. The third pin, normally a Yellow wire, is the left signal light; the top pin, normally a Green coloured wire, is the right signal light.

Re the round connector, from the notch in the plastic surround, clockwise, the first blade is ignition controlled +12VDC battery power, (only alive when engine running), and on the Land Rover factory harness is an Orange wire; on a NAS trailer, usually Red but perhaps a Black wire.

Next blade clockwise at 3:00 o'clock above, is the Right Turn signal light, a Green wire on the LR harness, and also on a NAS trailer.

At 5:00 o'clock, the next blade is for the Electric Brakes and is Blue on both the LR harness and on a NAS trailer.

The Ground wire is next, White on both the LR harness and on a trailer.

At 9:00 o'clock above, is the Left Turn signal, Yellow on both the LR harness and on a trailer.

The last blade to the left of the line up notch is the Tail Light circuit. On the LR harness, the wire colour is Brown with two White stripes and on a NAS trailer, Brown.

The centre pin is for the Reverse Back Up lights and is Black on the LR harness and often Purple on NAS trailer wiring but can be Black also.

Note that when the socket assembly is installed on the 3, the notch in the plastic surround is on the left - that is rotated 90 degrees anticlockwise to the picture above. In other words, When installed on the 3, the 4 pin flat connector lays horizontal and is located below the round socket.

|

|

CounterAct LT-2 Install Instructions169 viewsThese are the instructions for installing the CounterAct coupler pads (2) and the power supply.

|

|

Sound insulation installed50 views

|

|

Tailgate Camera located above license plate.594 viewsThis aftermarket camera is mounted on my 2005 LR3 in almost the same location as the factory cameras. The factory units are mounted somewhat more forward closer to the metal of the tail gate and I could have done the same as well.

Note that the camera above is aimed a bit towards the centreline of the vehicle per the factory install.

|

|

Aux Battery Installed1031 viewsIts a tight fit, but uses the LR battery mounts and bracket, slightly modified.

|

|

Installed and wired863 viewsShows the wiring loom to the isolator, the feeds (fused link) to the rear outlets and the other feeds are for the battery meter

|

|

Thread upload15 viewsImage uploaded in new thread

|

|

150t Air Seperation column South Africa95 viewsShows us lifting a 150 tonnes 50 metres long, Air Separation Column in South Africa, we were responsible from UK manufacturer up to installed onto foundations in SA.

|

|

Dual Headrest DVD installed45 views

|

|

Sirius Radio installed overhead58 views

|

|

Side Shot664 viewsSliders and plastic wheel arch mud guard, not installed....

|

|

SideSteps Installation Instructions495 viewsLR Official fitting instrutions for LR SideSteps

|

|

OEM Intsructions to install Side Steps8 views

|

|

Thread upload17 viewsImage uploaded in thread 132186

|

|

295 views

|

|

342 views

|

|

STC8138AB Generic Land Rover Fire Exinguisher4 viewsInstallation instructions for generic Land Rover fire extinguisher.

|

|

Upper Hatch Release Switch LR Part Number YUZ500020672 viewsThis is the Range Rover Sport switch, Land Rover part number YUZ500020, as it comes out of the box. Note the JAE, (Japanese Aviation Electronics), male wiring connector installed on the end of the power lead.

The rubber cover of the switch is sealed to the plastic body of the switch whereas in the previous switch design, there was no sealing. Also the replaced switch was hard wired into the same harness as the license plate lights - no JAE connector in other words.

|

|

![Filename=Technical Service Bulletin SB034 SB036 Vehicle Enhancement Program[1].pdf

Filesize=959KB

Dimensions=0x0